Hello friends, welcome to ELECTRICAL ENCYCLOPEDIA. In this article, we will study in depth about Underground Cables.

WHY SHOULD WE USE UNDERGROUND CABLES?

Underground Cables have several advantages over the conventional Overhead Lines like less maintenance cost , less chances of fault , less chances of getting being damaged due to environment. As well as underground cable provides better appearance. But the underground cables have higher installation cost and requires more insulation for same working voltage.

Underground Cables are generally employed where it is not possible to use Overhead Lines. Such areas may be thickly populated areas where safety is an important issue.

CONSTRUCTION OF UNDERGROUND CABLES

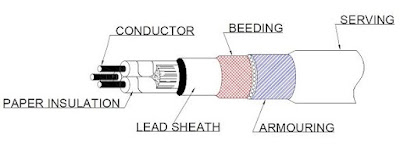

The various parts of 3 conductor cable are:

1. Cores/Conductor - Conductors used in underground cables are made up of tinned copper or aluminium. They are usually stranded in order to provide flexibility to the cable. A cable may have one or more than one conductor for eg, 3 phase cable will contain 3 conductors.

2. Insulation - Each core/conductor is properly provided with an insulation of suitable thickness which depends upon the voltage to be carried by the cable. Impregnated Paper, varnished cambric or rubber mineral compound is used for insulation purposes.

3. Metallic Sheath - Over the insulation, to protect the cable from moisture, gases, acid present in soil, a metallic sheath of lead or aluminium is provided.

4. Bedding - A layer of bedding consists of fibrous material like jute or hessian tape. Bedding protects the metallic sheath against corrosion and from any mechanical injury due to armouring.

5. Armouring - It consists of layer of galvanised steel wire or steel tape. Main purpose is to protect the cable from the damage due to laying the cable. Armouring may not be done in some cables.

6. Serving - It is a layer of fibrous material (like jute) which protects the armouring from atmospheric conditions. It is like bedding, bedding protects the metallic sheath and serving protects the armouring.

6. Serving - It is a layer of fibrous material (like jute) which protects the armouring from atmospheric conditions. It is like bedding, bedding protects the metallic sheath and serving protects the armouring.

PROPERTIES OF UNDERGROUND CABLES

1. Conductor used in the cable is generally made up of stranded copper or aluminium. Stranding is done because conductor may become flexible and carry more current.

2. Cable is provided with proper thickness of insulation in order to give high degree of safety and reliability. This avoids the leakage current.

3. Underground Cable have high mechanical strength to withstand the rough use in laying it.

4. Underground Cables are Non-Hygroscopic which means that it does not absorbs the moisture from soil because moisture decreases the insulation resistance and fastens the breakdown of the cable therefore, cables are enclosed in a water proof covering.

5. Underground Cables are non-inflammable.

6. Underground Cables remains unaffected by acids and alkalies present in the soil.

Thanks for reading.

Keep sharing & loving.