Welcome to ELECTRICAL ENCYCLOPEDIA. In this article, we will

study about the “Construction of Synchronous Machine”.

Unlike other electrical machines, In synchronous machine,

armature windings are placed on the stator and it has rotating field.

A Synchronous Machine consists of stator and rotor. Stator

is the stationary part of the machine and it carries the armature winding.

Output of the machine is taken from the stator.

Rotor is the rotating part of the machine. Field windings

are placed on the rotor and it produces the main field flux.

STATOR CONSTRUCTION

Various parts of the stator includes the frame, stator core,

stator windings and cooling arrangement. Frame may be of cast iron for

small-size machine and of welded steel for large-size machine. 3-phase winding also

called armature winding is placed in the slots cut on the inner periphery of the stator,

Stator core is assembled with thin sheets of high grade

silicon steel laminations.

Note that Armature Windings are placed in the Stator.

|

| STATOR OF ALTERNATOR |

ROTOR CONSTRUCTION

There are two types of rotor construction namely, salient

pole type and cylindrical rotor type.

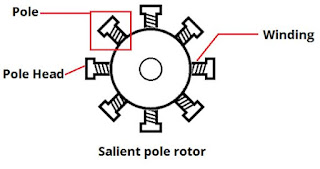

1. Salient-Pole Rotor

Term salient means ‘projecting’. Therefore, a salient pole

rotor consists of poles projecting out from the surface of the rotor core as

shown in the figure below.

As we can see from the figure, a salient-pole synchronous

machine has a non-uniform air gap. Air gap is minimum under the pole centres

and it is maximum in between the poles. The pole faces are so shaped that

radial air gap increases from the pole centre to the pole tips so that flux

distribution in the air gap is sinusoidal and it helps the machine to generate

sinusoidal emf.

Since the rotor is subjected to changing magnetic fields,

therefore it is made up of thin steel laminations to reduce eddy current loss.

Salient-pole rotor have concentrated windings on the pole.

Ends of the field winding are connected to the dc source through brushes on the

slip rings. DC source may be a dc generator which provides excitation to the

field windings.

Salient Pole Rotor has larger diameter and short axial

length as well as they operate at lower speeds. They have vertical configuration

installation.

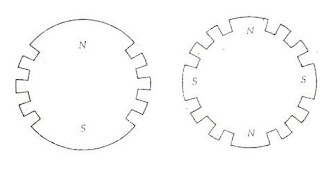

2. Cylindrical Rotor

Also called non-salient pole type rotor. Rotor is so

constructed that it forms a smooth cylinder and no physical poles are seen as

in salient pole type rotor.

|

| CYLINDRICAL ROTOR |

As shown in the above figure, two-third of the rotor

periphery, slots are cut at regular intervals and parallel to the shaft. DC

field windings are placed in these slots. Windings are of distributed type.

They have comparatively small diameter and long axial length. Because of

uniform air gap, its operation is less noisy and less windage losses.

Cylindrical Rotors are particularly used in high-speed

machines. They have horizontal configuration installation.

Thanks for reading.

Keep Sharing & Loving.