Welcome to ELECTRICAL ENCYCLOPEDIA. In this article, we will discuss about the Linear Induction Motor.

Linear Induction Motor is a special asynchronous motor which is designed in such a way that it produces linear/translational motion instead of rotational motion. Linear Induction motor is really an Electrical Engineering Marvel.

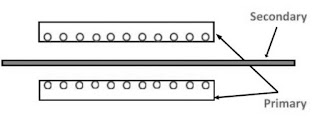

Another variant of the Linear Induction motor is Double sided Linear Induction motor in which primary is provided on the both sides of the secondary to effectively utilize the flux distribution.

If we keep the primary fixed and secondary free to move, then force will move the secondary in the direction of travelling flux wave and result in the linear motion of the secondary.

Linear Synchronous speed, Vs of the travelling flux wave is given by:

Vs = 2*f*t metre/sec

where, f = supply frequency in Hz.

p = pole pitch, which is pole to pole linear distance on primary

Since in the conventional Induction Motor, speed of the rotor is less than the synchronous speed. Same is true for the Linear Induction motor, speed of the secondary is less than the synchronous speed. It is given by

Vr = Vs * (1 - s)

where, s = slip of linear induction motor

Linear Induction Motor requires a larger air gap.Therefore, magnetizing current is larger and power factor and efficiency are generally low than the conventional induction motor for similar rating.

1. Metallic Conveyor belts.

2. Automatic Sliding doors

3. In cranes for Material Handling, pumping of liquid metal

4. Also used in Electric Traction in some places, but very uncommon practise.

Thanks for reading.

Keep Sharing and Loving.

Linear Induction Motor is a special asynchronous motor which is designed in such a way that it produces linear/translational motion instead of rotational motion. Linear Induction motor is really an Electrical Engineering Marvel.

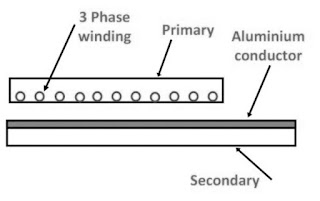

CONSTRUCTION OF LINEAR INDUCTION MOTOR

Basic Construction of Linear Induction Motor is similar to the conventional induction motor but its design is somewhat different. If the stator of the conventional induction motor is cut and laid on the flat surface, then it forms the primary of linear induction motor. Similarly, if rotor is also cut then it forms the secondary of the linear induction motor. Generally secondary of linear induction motor is of flat aluminium conductor with a ferromagnetic core. |

| LINEAR INDUCTION MOTOR |

|

| DOUBLE SIDED LINEAR INDUCTION MOTOR |

WORKING OF LINEAR INDUCTION MOTOR

When 3 phase supply is connected to the conventional Induction Motor, a rotating flux rotating at synchronous speed is produced. Similarly in linear Induction Motor, when 3 phase supply is connected to the primary, a travelling flux wave is produced that travels along the length of primary. EMF is induced in the aluminium conductor (secondary) due to the relative motion between travelling flux wave and aluminium conductor and it in turns, produces a linear force called thrust.If we keep the primary fixed and secondary free to move, then force will move the secondary in the direction of travelling flux wave and result in the linear motion of the secondary.

Linear Synchronous speed, Vs of the travelling flux wave is given by:

Vs = 2*f*t metre/sec

where, f = supply frequency in Hz.

p = pole pitch, which is pole to pole linear distance on primary

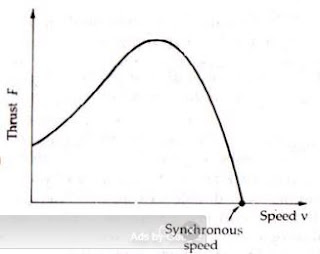

Since in the conventional Induction Motor, speed of the rotor is less than the synchronous speed. Same is true for the Linear Induction motor, speed of the secondary is less than the synchronous speed. It is given by

Vr = Vs * (1 - s)

where, s = slip of linear induction motor

Linear Induction Motor requires a larger air gap.Therefore, magnetizing current is larger and power factor and efficiency are generally low than the conventional induction motor for similar rating.

|

| THRUST- SPEED CURVE OF LINEAR INDUCTION MOTOR |

APPLICATIONS OF LINEAR INDUCTION MOTOR

Due its lower efficiency and taking cost into consideration, Linear Induction Motor does not finds its many applications. Although it is used for some specialized operations like1. Metallic Conveyor belts.

2. Automatic Sliding doors

3. In cranes for Material Handling, pumping of liquid metal

4. Also used in Electric Traction in some places, but very uncommon practise.

Thanks for reading.

Keep Sharing and Loving.